Battery Laboratory

The transformation of transport and energy is gaining increasing momentum causing significant challenges for politics, industry, and society. The expansion of the application of renewable energie sources necessicate technological solutions to stabilize the energy supply grid. Moreover, the number of mobile electric appliances is steadily increasing, rendering having reliable battery storage systems crucial.

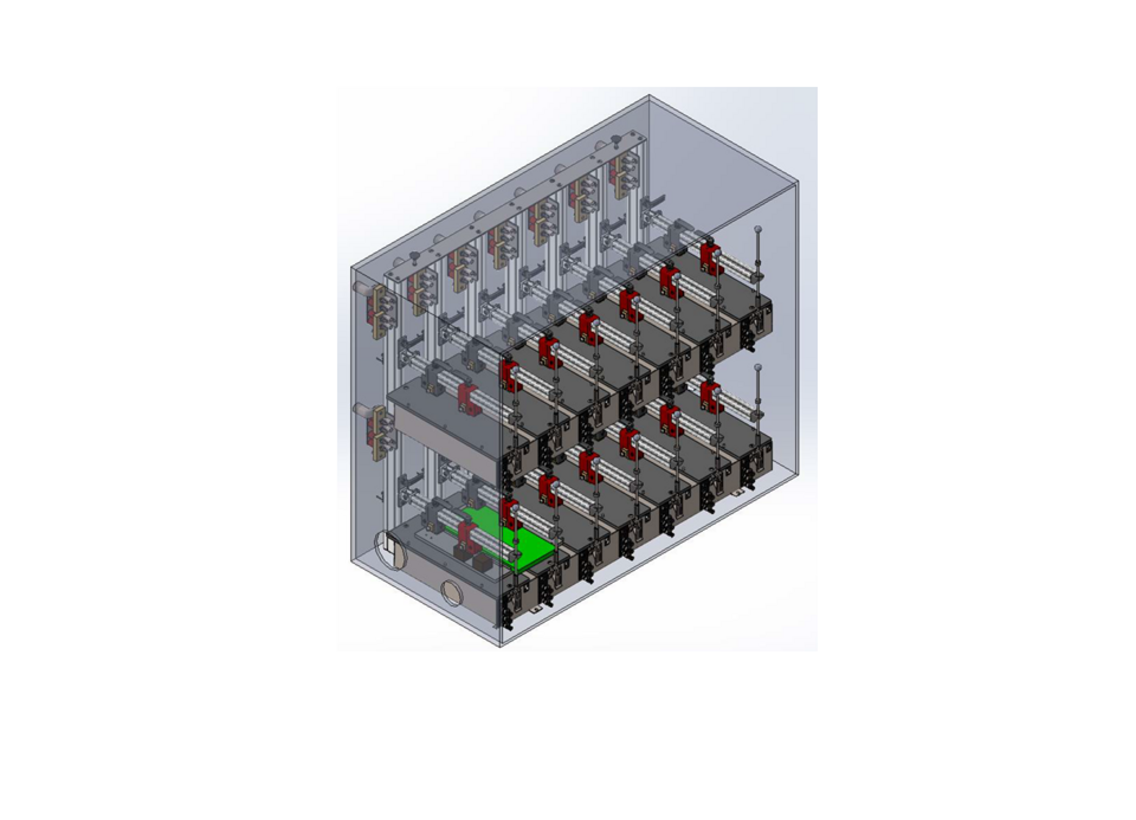

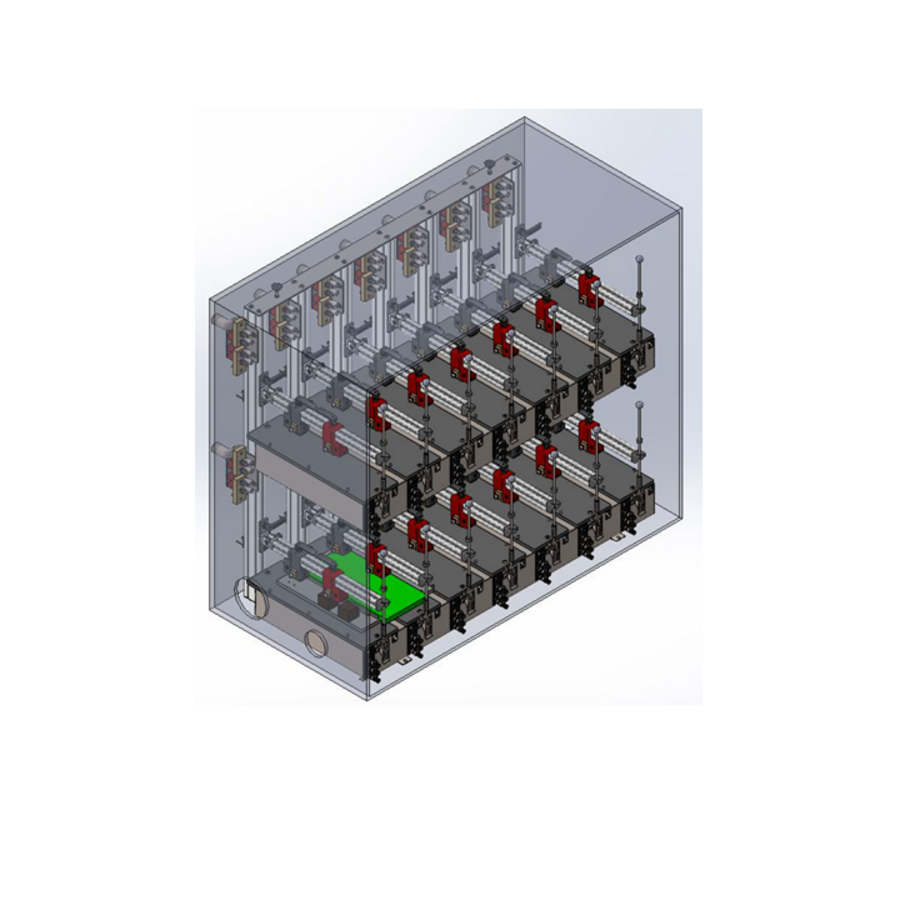

The battery laboratory of the Institute of Electromobility and Energy Storage Systems, which will be put into operation in 2022, offers the opportunity for in-depth research into scientific issues arising from the related challenges mentioned earlier. For this purpose, the institute has various testers and temperature cycling cabinets at its disposal that enable battery research at both cell and module levels and allows for running different battery management systems (BMS) tests.

Module Tester (Keysight SL1001A)

| Number of Channel | 4 |

| I per Channel | ± 300 A |

| U per Channel | 5-90 V |

| P per Channel | ± 24 kW |

| Current Accuracy | ± 0.05 % (± 60 mA) |

| Voltage Accuracy | ± 0.05 % (± 18 mV) |

| Temperature Channel |

3x PT 100 per measuring channel |

| Further |

Electrochemical impedance spectroscopy |

Cell Tester (Keysight SL1007A)

| Number of Channel | 16 |

| I per Channel | ± 25 A |

| U per Channel | 0-6 V |

| P per Channel | ± 150 W |

| Current Accuracy | ± 0.05 % (± 2.5 mA) |

| Voltage Accuracy | ± 1 mV |

| Temperature Channel |

1x PT 1000 per measuring channel |

| Further |

Electrochemical impedance spectroscopy |

Cell Tester (Keysight SL1007A)

BMS Tester (Keysight SL1010A)

| Number of Channel | 32 |

| I per Channel | ± 5 A |

| U per Channel | 8 V |

| P per Channel | 40 W |

| Further |

Electrochemical impedance spectroscopy |

Temperature Cycling Cabinet (Binder MK720)

| Temperature Range | -40 to +180°C |

| Further | 2 independent over-temperature limiter |

| Heated stainless steel overpressure flap | |

| Door safety device with reinforced clamps on the closing side | |

| Inert gas connection for on-site gas connection/nitrogen purging |

Temperature Cycling Cabinet (Binder MK115)

| Temperature Range | -40 to +180°C |

| Further | 2 independent over-temperature limiter |

| Heated stainless steel overpressure flap | |

| Door safety device with reinforced clamps on the closing side | |

| Inert gas connection for on-site gas connection/nitrogen purging |

Cell Contact System (Voltavision KS-600-14C)

| Number of Channel | 14 |

| Current | up to 600 A |

| Further | Fast and reproducible contacting of prismatic and pouch cells |

| Prismatic Cells | according to DIN 91252:2016-11: HEV1, PHEV2, HEV1, HEV2, BEV1 bis BEV4 |

| Pouch Cells |

according to DIN 91252:2016-11: HEV, PHEV1, PHEV2, BEV |

Cell Contact System (Voltavision KSR-150)

| Number of Channel | 2 x 8 channels |

| Current | up to 150 A |

| Further | Fast and reproducible contacting of cylindrical cells |

| Suitable for a wide range of diameters | |

| Usable under highest stresses and test conditions |

The battery laboratory was financed with funding from the program "Major Equipment of the Federal States".

Further information can be found in the following article: Use Study Uni Wuppertal.