Development of an efficient, durable and cost-effective drive train for electric vehicles

Project Duration:

Juny 2013 - October 2015

Consortium:

- University of Wuppertal

(Chair EES)

- FH Südwestfalen

(FB Maschinenbau und Automatisierungstechnik)

Funding:

Zentrales Innovationsprogramm Mittelstand (ZIM)

Federal Ministry for Economic Affairs and Energy (BMWi)

Description

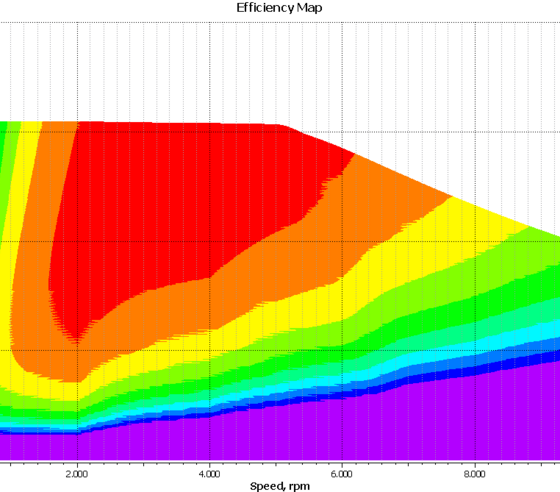

Against the background of economic efficiency, an innovative, highly integrated drive train for electric vehicles was developed as part of the project "Development of an efficient, durable and cost-effective drive train for electric vehicles". Maximum efficiency of the engine and transmission, maximum recuperation of braking energy, a long service life without maintenance and the economical production of a marketable drive train were the declared goals and, overall, lead to a reduction in mobility costs compared to conventionally operated vehicles.

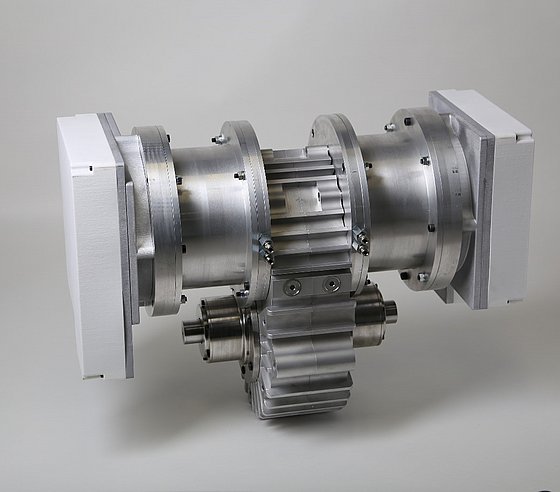

State of the art are drives consisting of separate components such as control converters, electric motors and gears. This requires interfaces for electrical contacts and separate contacts for cooling. In addition to the additional costs associated with this, the service life is also negatively affected, since each of these connections and components increases the risk of failure. This risk of failure can be significantly reduced by the highly integrated design by reducing the number of plugs, cables and seals and making the technical design of the individual subassemblies simpler. In addition, a highly integrated drive train leads to a reduction in installation space and weight, so that the required use of resources can be directly reduced compared to conventional drive systems. This not only results in a sustainable use of resources, but also a cost reduction in the later series production of a highly integrated drive train. In addition, the integration of the power electronics into the electrical machine reduces the cooling effort, since the electrical machine and power electronics can be cooled by a common cooling system.

In order to achieve the stated goals, the project partners each concentrated on the different focal points of the drive train. The overall concept of the system was the responsibility of Online Engineering GmbH in close cooperation with the partners. The partners carried out the following work areas: Online Engineering GmbH developed the control and power electronics and tested the motor with the electronics. The engine calculations (design and adjustment or optimization) were carried out by the University of Wuppertal. The South Westphalia University of Applied Sciences took on the development of the gearbox, motor housing with bearings and the entire housing.

Fig. 1: Drive train prototype

Fig. 2: Efficiency map of the electric machine